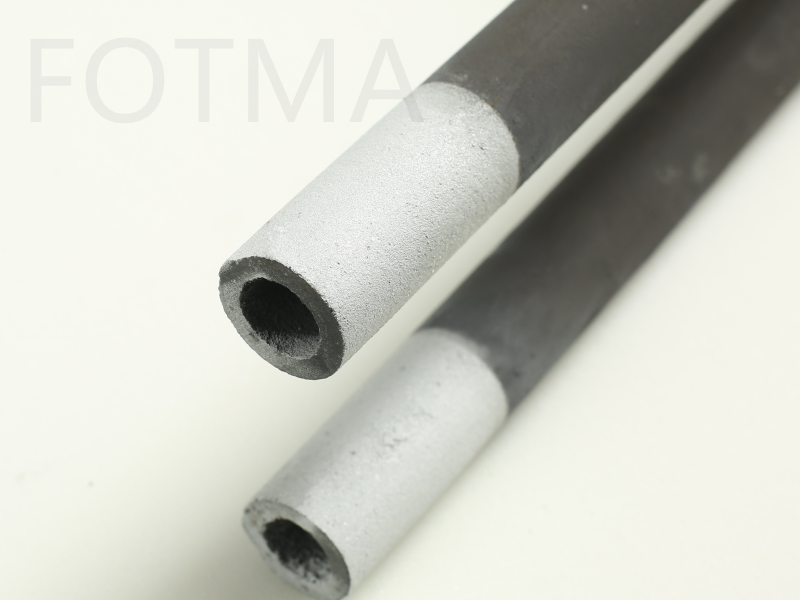

ED(RR) rod type silicon carbide heating elements

The ED Type is the standard Torch Furnace SiC heating element. A high-density self-bonded silicon carbide element, ED type is available in a large range of diameters and lengths.

This type of element is available in the following cold end types:

One Piece ED -- The cold ends are impregnated with silicon metal to reduce their resistance. This type is highly stable at temperatures up to 1600 deg C.

Three Piece ED -- Features welded-on low resistance cold ends which run cooler than any one-piece cold ends. Therefore, they are more energy efficient. Maximum temperature is 1600 deg C.

ED was created to help reduce heat loss within the furnace reducing the overall energy consumption. Most furnaces lose their heat from four parts: the kiln wall, products being treated, vessels and crucibles, and the cold ends of SiC heating elements.

To combat the issue with cold ends, Torch Furnace ED was developed as a heater, keeping the same properties of standard elements, but with new cold ends with a resistance of 1/3 times less than that of the standard element, resulting in approximately 4% energy savings.

Also, the lower temperature of the cold ends of Torch Furnace ED, saves the cost to cool down the gas tighten terminal boxes of furnaces. These savings prove to be the most substantial in Float Bath applications due to this larger furnace type. And because Torch FurnaceED can be produced in the same sizes and electric characteristics of the existing elements, replacement and/or substitution is easily achieved. Torch Furnace ED silicon carbide SiC heating elements, composed of high-purity, recrystallized silicon carbide, have earned the reputation as the world's leading heating elements. These elements are widely used as high-temperature heat sources for electric furnaces and for the firing of ceramic capacitors, ferrites and other electronic components Features Withstands temperatures as high as 1600°C Generates high heat output per unit surface area, approximately 5- 10 times the output of Nichrome wire High strength and excellent shock resistance Chemically stable Heat source is free of noise and air pollution Various coating products are available for protection against water vapor and harmful gas atmosphere Easy to handle Higher density resulting in longer life Wide variety of shapes available.

OD: Outer diameter, HZ: Hot zone, CZ: Cold zone, OL: Overall length, Resistance: Ohms (92)

Examples: ED, dia / hot zone length /Overall Length/ resistance

ED20/300/900/2.24