FM600-Q1 Series Pneumatic High Temperature High Pressure Ball Valves

Basic Description

Nominal Diameter:DN15~200mm

Full-bore design, fast response, zero leakage.

Fireproof and anti-static structure, silica sol precision casting, safe and reliable.

Compliant with ISO5211 standard high platform design, long service life.

Two-way sealing, two-way pressure bearing, automatic compensation, self-cleaning function.

Suitable for fibrous, particle-containing and high-viscosity media.

Technical Parameters

|

| DN | DN15~200mm |

| Nominal Pressure | 1.6-42Mpa ( lf need other standard、please indicate when ordering ) |

| Body Material | Carbon steel(C)、Stainless 304(P)、Stainless 316(R) |

| Seal Material | PTFE(F)、PPL(PPL)、Metal Hard Sealed(H)、Hard Alloy(Y) |

| Media Temperature | W2:-20~150℃ W3:-20~250℃ W4:-29~425℃ |

| Connection Mode | Flange、Butt welding、Female thread |

| Pneumatic Actuatcr | FMAT series、FMAW series、lmport actuator series |

| Interaction Way | Double action、Single acting normally closed、Single acting normally open |

Notes: 1. The valve body adopts the forging process, and the forms are divided into floating type, fixed type, and top-loading type; the seal is divided into soft seal and hard seal, the pressure resistance is up to 2500 pounds, and the temperature resistance is as low as -196°C and up to 570°C.

2. Other special sealing material or special temperature can choose by customer's design.

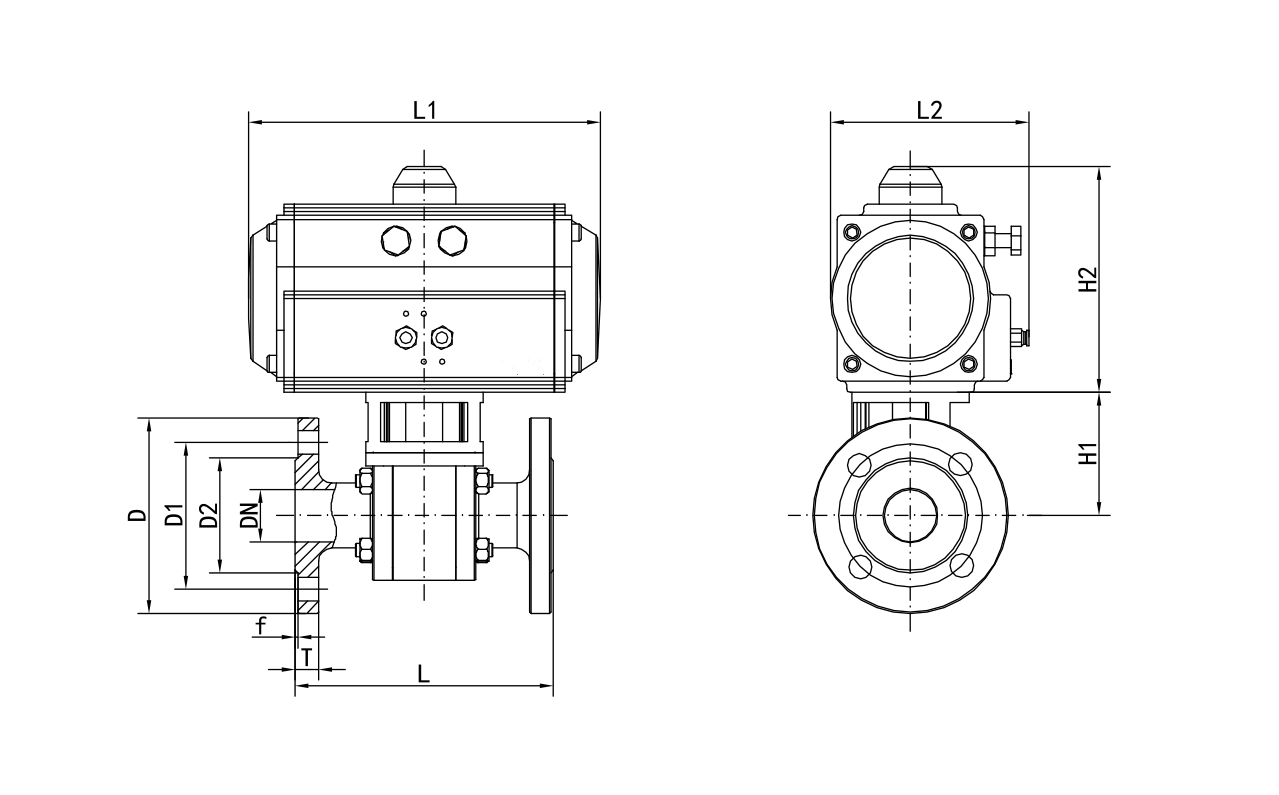

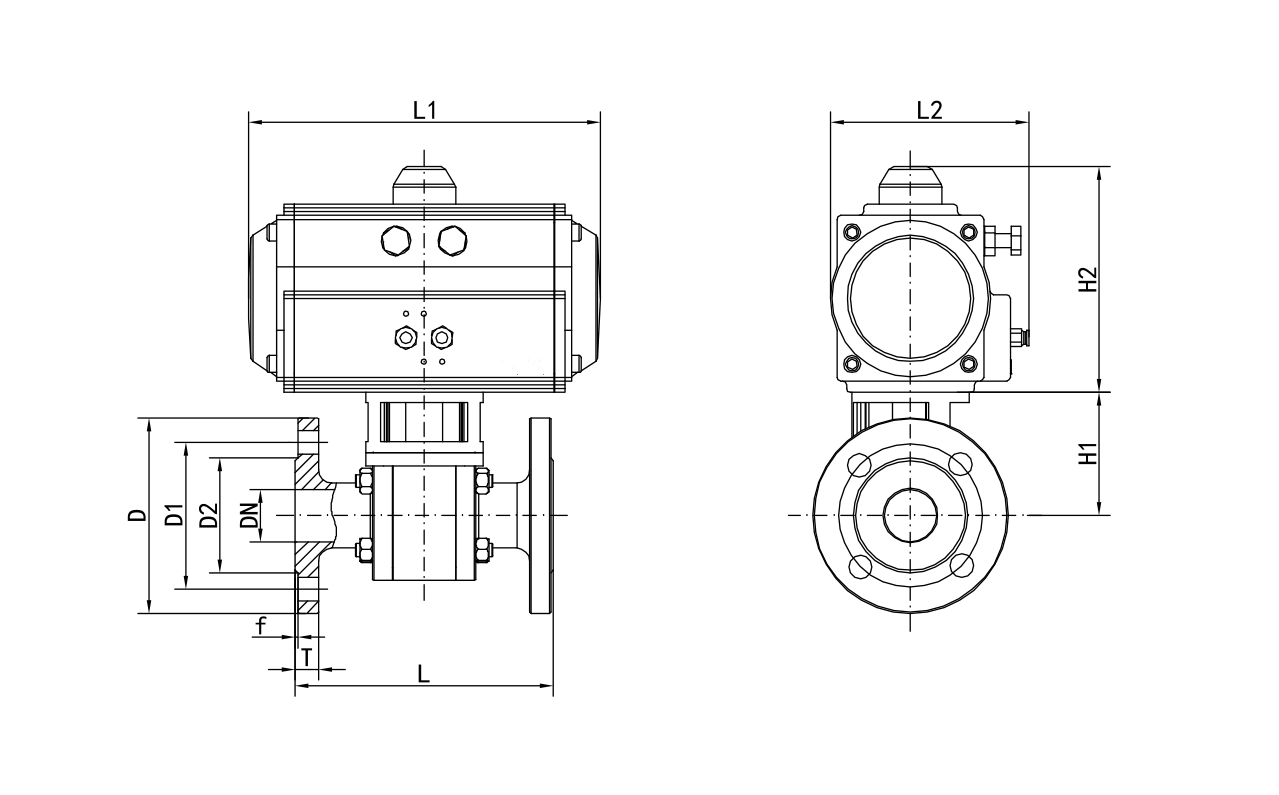

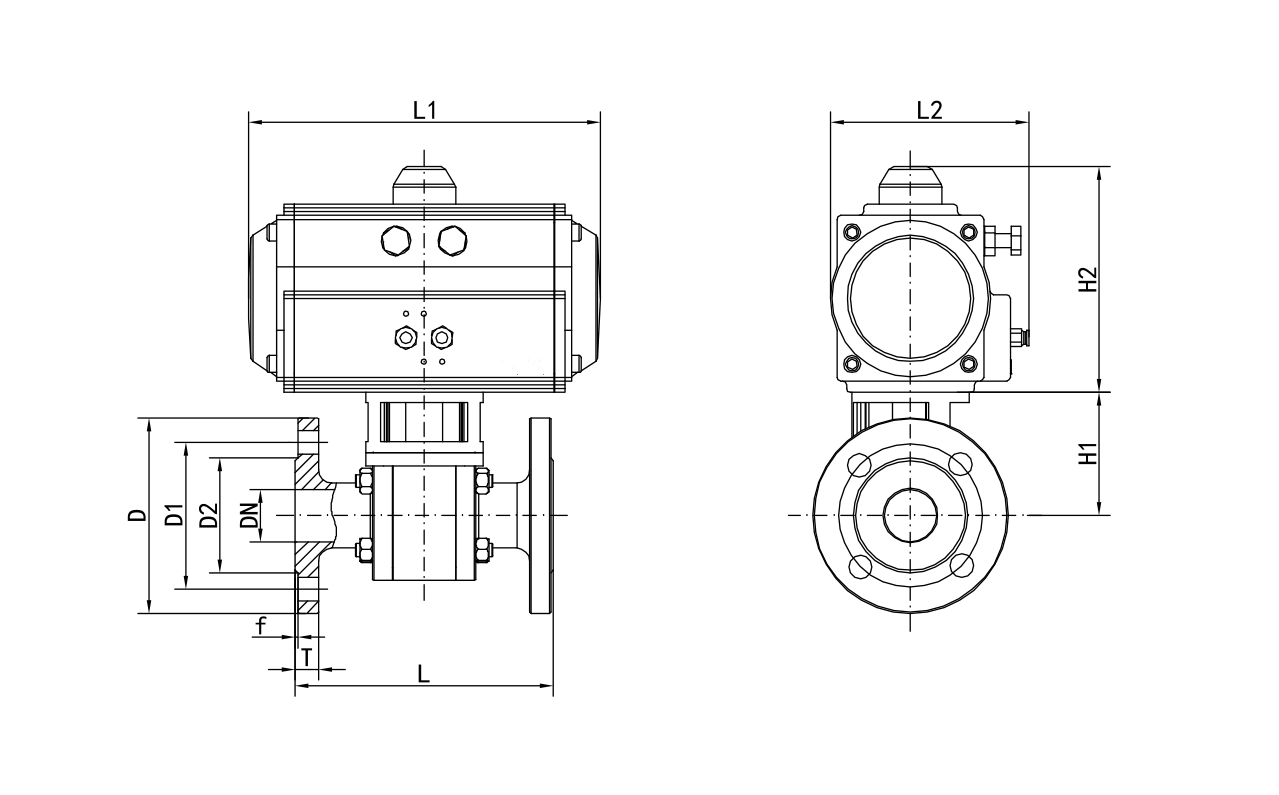

Installation Size

PNEUMATIC OVERALL MEASUREMENT CHART-PN 110(110bar)

| DN | Outline Size | Connection Size |

| NPS | L(RF) | L(BW) | L(RTJ) | D | D1 | T | n-d |

| 15 | 1/2 | 165 | 165 | 163.5 | 105 | 75 | 20 | 4-14 |

| 20 | 3/4 | 191 | 191 | 191 | 130 | 90 | 22 | 4-18 |

| 25 | 1 | 216 | 216 | 216 | 140 | 100 | 24 | 4-18 |

| 32 | 11/4 | 229 | 229 | 229 | 155 | 110 | 26 | 4-22 |

| 40 | 11/2 | 241 | 241 | 241 | 170 | 125 | 28 | 4-22 |

| 50 | 2 | 292 | 292 | 295 | 195 | 145 | 30 | 4-26 |

| 65 | 21/2 | 330 | 330 | 333 | 220 | 170 | 34 | 8-26 |

| 80 | 3 | 356 | 356 | 359 | 230 | 180 | 36 | 8-26 |

| 100 | 4 | 432 | 432 | 435 | 265 | 210 | 40 | 8-30 |

According to different torques, different air source pressures and different actual working conditions, select the corresponding actuator and its relevant external dimensions also change. Model Description Model Denotation Mode

| FM | Company Brand

|

| -600 | Pneumatic

|

| -Q1 | 2 Way Valve |

| -C4 | Flange

|

| -H | Metal Hard Sealing

|

| -250 | Nominal Pressure

|

| -P | Stainless 304

|

| -40 | Nominal Diameter

|

| -Z | Standard Switch Type

|

| -B | Exd Ⅱ BT4

|

| -W4 | -29~425℃

|

| - | Attachment Select

|

| - | Attachment Select

|

Product Usage FPSO (Floating Production Storage Tanker) and FLNG (Floating Liquefied Natural Gas System) are the main production methods in the offshore oil and gas industry. Due to its special location and environment, there are many challenges in the construction, operation and maintenance of FPSO&FLNG. The characteristics of corrosion, high pressure, seawater, deep sea and other working conditions require that valves used in FPSO and FLNG systems need to be specially designed and manufactured, using corrosion-resistant materials, seals and external special coatings. Juliang Valve can provide ball valves, butterfly valves, gate valves, globe valves and check valves specially used in FPSO and FLNG systems. Based on the stability, reliability and safety of the products, the products are also widely used in many FPSO&FLNG projects.