FM600-Q15 Series Pneumatic Lined Ceramic Valves

Basic Description

Nominal Diameter:DN15~250mm

High-performance structural ceramics, self-cleaning, super wear-resistant, strong corrosion.

Tensile strength, compressive strength, good toughness, high hardness, long service life.

Good circulation, reliable sealing, long service life and wide use environment.

Suitable for boiler steam, lime slurry, seawater containing particles, high hardness particles.

Contains soft particles and corrosive media, powder, flue gas desulfurization, ash discharge, slag discharge, water treatment.

Technical Parameters

| Technical Parameter |

| DN | DN15~250mm(Please indicate if need other DN when ordering) |

| Nominal Pressure | 1.0-1.6Mpa ( lf need other standard、please indicate when ordering ) |

| Body Material | Carbon steel(C)、Stainless 304(P)、Stainless 316(R) |

| Seal Material | Engineer Ceramic |

| Media Temperature | W3: -20~250℃ |

| Connection Mode | Flange |

| Pneumatic Actuatcr | FMAT series、FMAW series、lmport actuator series |

| Interaction Way | Double action、Single acting normally closed、Single acting normally open |

Notes: Other special sealing material or special temperature can choose by customer's design.

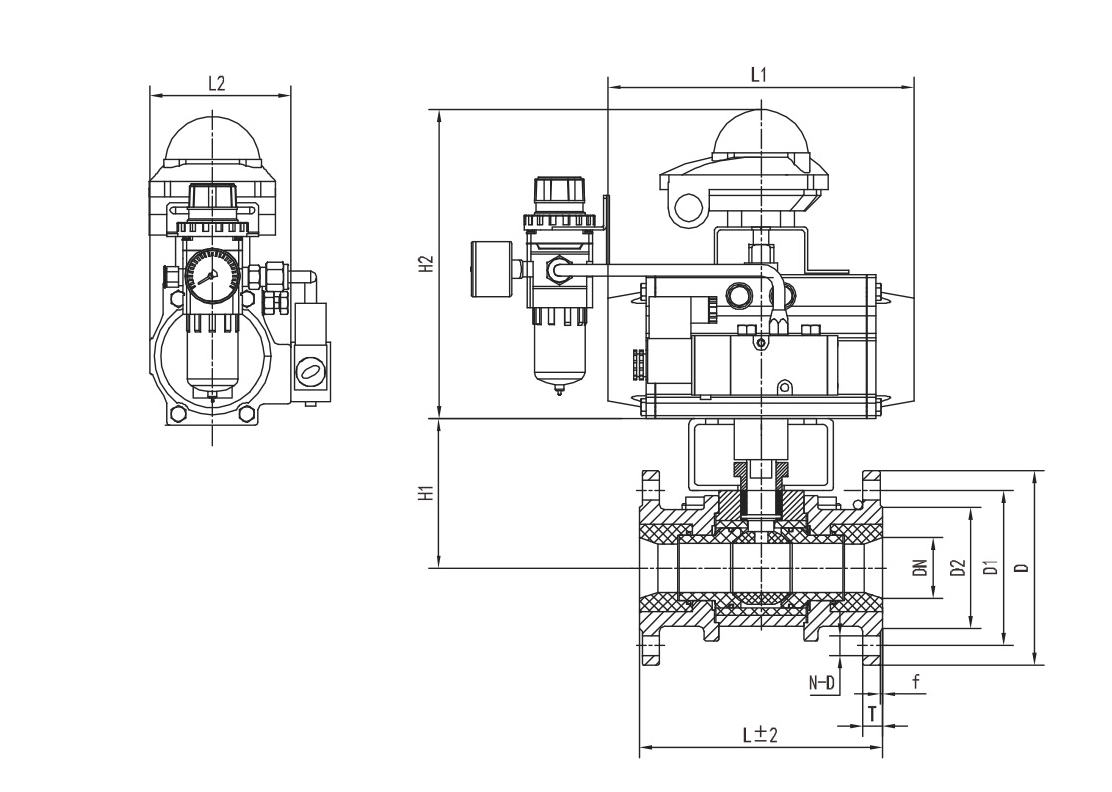

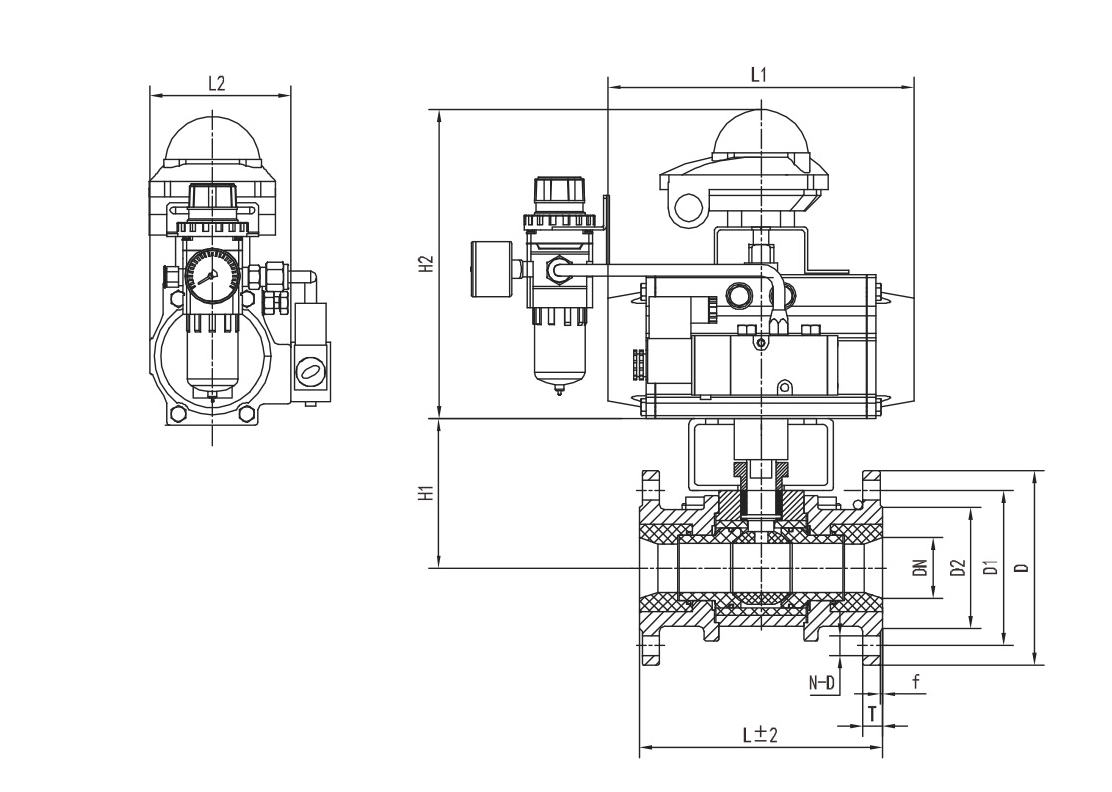

Installation Size

PNEUMATIC OVERALL MEASUREMENT CHART-PN 16(16bar)

| DN | Outline Dimension | Connection Dimension | Actuator Model |

| L | L1 | L2 | H1 | H2 | D | D1 | D2 | T | f | N-D |

| 15 | 130 | 159/172 | 73/85 | 88 | 73/90 | 95 | 65 | 46 | 14 | 2 | 4-14 | FMATD52/FMATE63 |

| 20 | 130 | 172/215 | 85/105 | 93 | 90/110 | 105 | 75 | 56 | 16 | 2 | 4-14 | FMATD63/FMATE83 |

| 25 | 140 | 185/215 | 95/105 | 100 | 100/110 | 115 | 85 | 65 | 16 | 2 | 4-14 | FMATD75/FMATE83 |

| 32 | 165 | 185/265 | 95/110 | 120 | 100/120 | 140 | 100 | 76 | 18 | 2 | 4-18 | FMATD75/FMATE92 |

| 40 | 165 | 265/270 | 110/125 | 126 | 120/142 | 150 | 110 | 84 | 18 | 2 | 4-18 | FMATD92/FMATE105 |

| 50 | 203 | 270/310 | 125/142 | 135 | 142/158 | 165 | 125 | 99 | 20 | 2 | 4-18 | FMATD105/FMATE125 |

| 65 | 222 | 310/400 | 142/160 | 170 | 158/178 | 185 | 145 | 118 | 20 | 2 | 4-18 | FMATD125/FMATE140 |

| 80 | 241 | 310/400 | 142/160 | 185 | 158/178 | 200 | 160 | 132 | 20 | 2 | 8-18 | FMATD125/FMATE140 |

| 100 | 305 | 400/465 | 160/178 | 215 | 178/200 | 220 | 180 | 156 | 22 | 2 | 8-18 | FMATD140/FMATE160 |

| 125 | 356 | 465/550 | 178/210 | 225 | 200/235 | 250 | 210 | 184 | 22 | 2 | 8-18 | FMATD160/FMATE190 |

| 150 | 394 | 550/646 | 235/258 | 230 | 260/325 | 285 | 240 | 211 | 24 | 2 | 8-22 | FMATD210/FMATE240 |

| 200 | 457 | 646/722 | 258/292 | 260 | 325/352 | 340 | 295 | 266 | 24 | 2 | 8-22 | FMATD240/FMATE270 |

| 250 | 533 | - | - | 290 | - | 395 | 350 | 319 | 26 | 2 | 12-22 | - |

According to different torques, different air source pressures and different actual working conditions, select the corresponding actuator and its relevant external dimensions also change.

Model Description

Model Denotation Mode

| FM | Company Brand

|

| -600 | Pneumatic

|

| -Q15 | Ceramic Ball Valve

|

| -C4 | Flange

|

| -TC | Lined Ceramic

|

| -16 | Nominal Pressure

|

| -C | Carbon Steel

|

| -50 | Nominal Diameter

|

| -E1 | Single Action Normally Closed

|

| - | Anti-explosion Class

|

| -W3 | -20~250℃

|

| -B1 | 2 Bits 3 Way Solenoid Valve

|

| -B7 | Anti-explosion Limit Switch

|

Product Usage FM600-Q15 new ceramic ball valve is a new material using the characteristics of corrosion resistance, wear resistance and high hardness of structural ceramics, and is designed by scientific structure optimization. Widely used in power plant desulfurization system, washing and beneficiation system, fluid flow control system, chemical industry and other strong corrosion occasions. Application areas: thermal power plants, steel, petroleum, chemical industry, papermaking, bioengineering, electric power, metallurgy, mining, sewage treatment, boiler steam, lime slurry, particle-containing seawater transportation, high-hardness particles, soft particles and corrosive media , powder, flue gas desulfurization, ash discharge, slag discharge, water treatment and other industrial fields, especially in the face of high wear, strong corrosion, high temperature, high pressure and other harsh working conditions.