Ground control assembly

Brief introduction:

During the cause of test ,fluid should be controllably guided into separator and burner after flowing through drilling rod or tubing, the assembly is named as control assembly, which can control the pressure and flow-rate of the fluid safely and effectively.

1. Control Head

Jointed with the upper of the test string, control head is classified into rotary head and un-rotary head of two kinds, and also into three kinds of 35MPa.70MPa and 105MPa according to the bearing pressure,and it can let the high-pressure fluid flow out of string,but also pump fluid into well.

2. Rigid manifold

Used to control fluid pressure and flow-rate,rigid manifold is jointed with control head upwards and connected with separator and blowout pipeline downwards.

The working pressure includes 35MPa,70Ma and 105MPa with appropriate test pressure of 70MPa,105Ma and 140MPa .

3. Active manifold

Used to joint the control head, rigid manifold and blowout pipeline, the manifold consists of special EUE seamless steel pipeline union and active elbow .The working pressure includes 35MPa,70Ma and 105MPa with appropriate test pressure of 70MPa, 105Ma and 140MPa.

The manifold should be regularly inspected and lubricated,sealing ring should be replaced and sealing tested to ensure safety in test .

| Item | Component | Qty | Material |

| 1 | Pressure Gauge | 1 | Standard |

| 2 | Needle Valve | 4 | |

| 3 | Buffer | 1 | |

| 4 | Tee | 1 | 4130 |

| 5 | Elbow | 1 | 4130 |

| 6 | Plug Valve | 1 | |

| 7 | lee | 1 | 4130 |

| 8 | Check Valve | 4 | |

High-pressure union

Brief introduction:

High-pressure union ,importing international advanced technology. is forged with high-strength alloy steel,strict heat treatment process can ensure that the nipple have uniform metallurgical structure and pressing ability and the material meets ASTM and AISI Standard and the technology indexes conform to API Spec 6A,the product adopts the product adopts some end connections of pipeline thread, tubing thread, butt-weld and compress- -seal.

| Item | Component | Qty | Material |

| 1 | Male Sub | 1 | 4130 |

| 2 | Nut | 1 | 5140 |

| 3 | Seal Ring | 1 | NBR |

| 4 | Female Sub | 1 | 4130 |

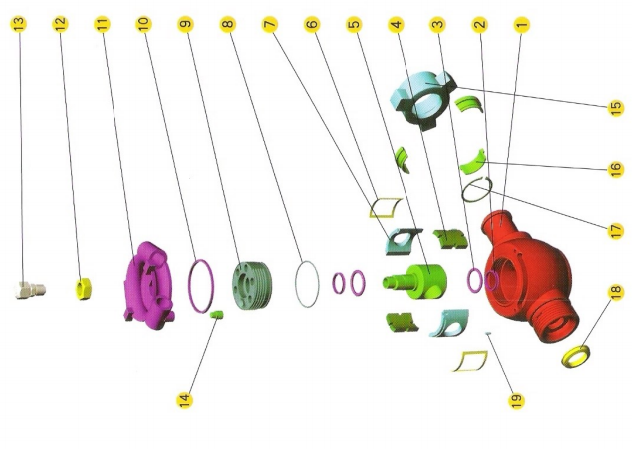

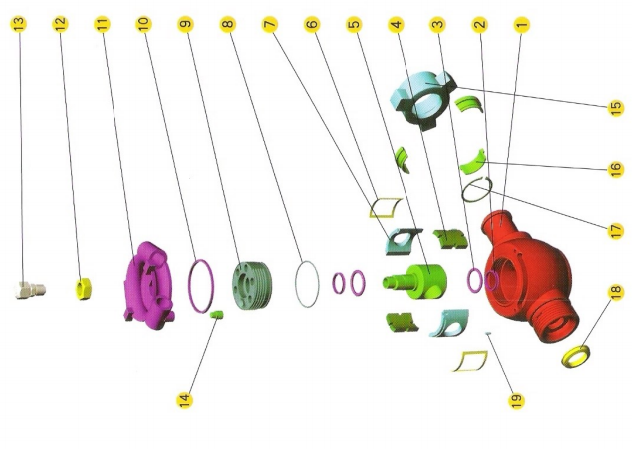

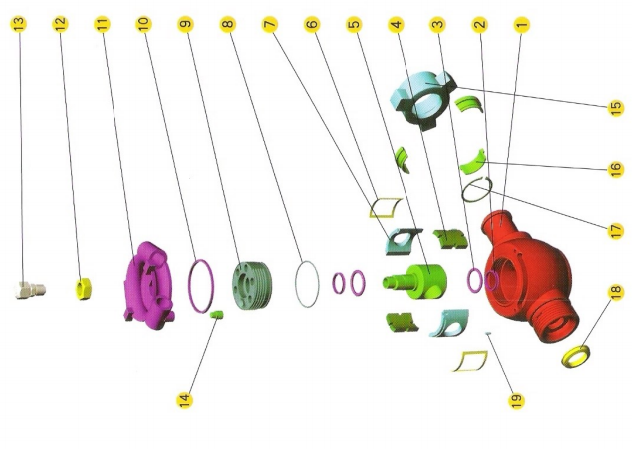

Ground Control--Plug Valve

Brief introduction:

Plug valve is a key part that is connected with high-pressure manifold in operation of cementing well and fracture in oil field and also suitable to high-pressure fluid control.

Notice: Under the 10000PSI pressure, the valve can be easily opened or closed .

Operation & Application:

Plug valve shall be clean and high- -pressure grease shall be injected into valve chamber in time,otherwise there may be leakage on the outlet.

Before usage, it should be inspected whether the opening/ closing situation be in line with sign and hand wheel turning at 90 degree can create open/ close.

Maintenance

Constant maintenance can prolong the working life of valve;

The clean and injection of oil/grease should be executed after work is over.

Regularly check whether all seals is damaged, the damaged seal should be replaced immediately;

As the seal of the piston and liner fail, it should be disassembled and inspected, it can be polished or replaced.

| Item | Component | Qty | Material | Code |

| 1 | Body | 1 | 4130 | SH- -PV-xx-xx-01 |

| 2 | Packing | 2 | 1010 | SH- -PV-xx-xx-02 |

| 3 | O-Ring | 2 | NBR | SH- -PV-xx-xx-03 |

| 4 | Side Segment | 2 | 410 | SH- -PV-xx-xx-04 |

| 5 | Plug | 1 | NBR | SH- -PV-xx-xx-05 |

| 6 | Seal:F/Seal Segment | 2 | Rubber | SH- -PV-xx-xx-06 |

| 7 | Seal Segment | 2 | 410 | SH- -PV-xx-xx-07 |

| 8 | O-Ring | 1 | NBR | SH- -PV-xx-xx-08 |

| 9 | Body Cap | 1 | 4130 | SH- -PV-xx-xx-09 |

| 10 | O-Ring | 1 | NBR | SH- -PV-xx-xx-10 |

| 11 | Plug Cap | 1 | WCB | SH- -PV-xx-xx-11 |

| 12 | Nut: Lock ,Hex | 1 | 5140 | SH- -PV-xx-xx-12 |

| 13 | Grase Fitting | 1 | Assembly | SH- -PV-xx-xx-13 |

| 14 | Locating Pin | 1 | 1045 | SH- -PV-xx-xx-14 |

| 15 | Detachable Nut | 1 | 1045 | SH- -PV-xx-xx-15 |

| 16 | Retainer Segment | 3 | 5140 | SH- -PV-xx-xx-16 |

| 17 | Retainer Ring | 1 | 1566 | SH- -PV-xx-xx-17 |

| 18 | Seal Ring | 1 | Rubber | SH- -PV-xx-xx-18 |

| 19 | Stop Pin | 1 | 410 | SH- -PV-xx-xx-19 |

High-pressure union: