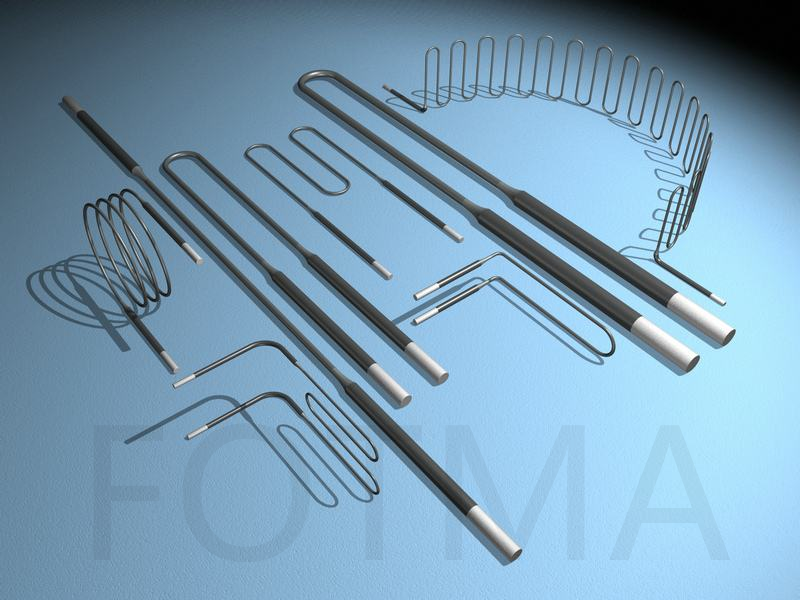

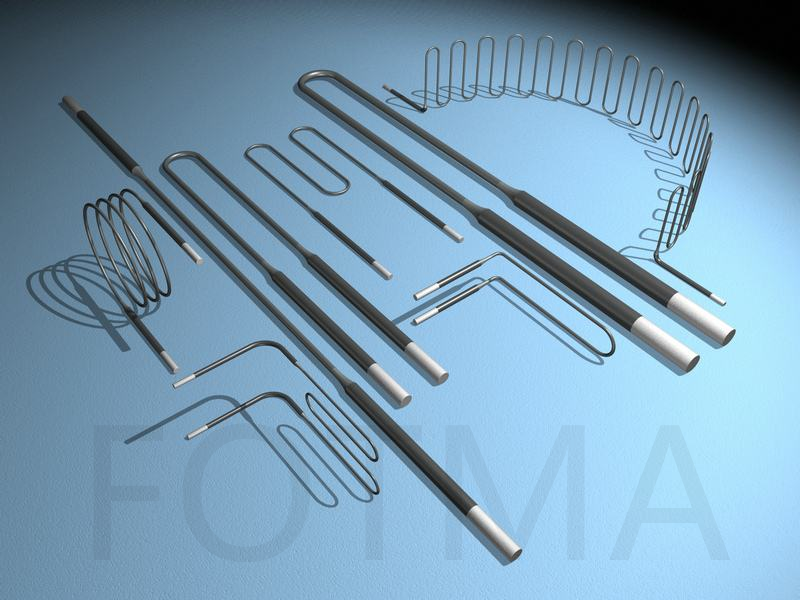

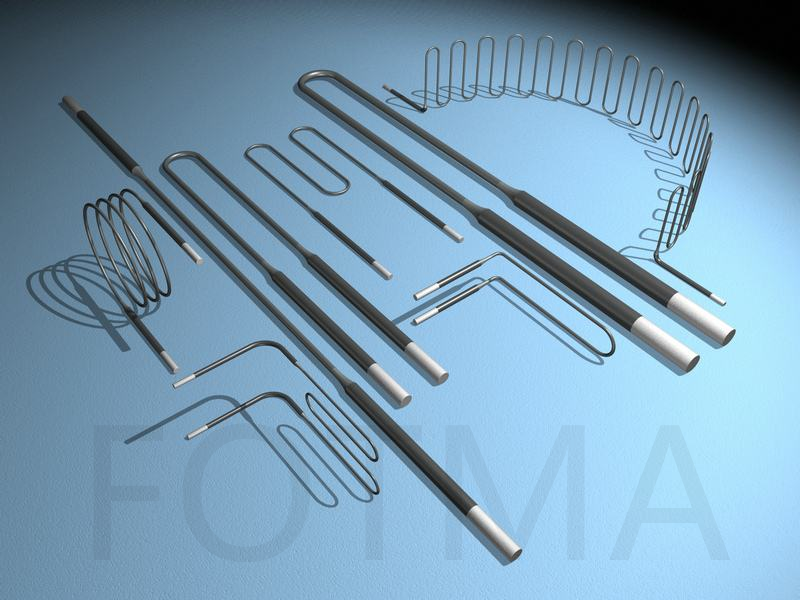

Special Shape Molybdenum Disilicide Heating Element

Description: The MoSi2 heating element is a dense cermet material consisting of MoSi2 and an oxide, glassy phase component.

Molybdenum disilicide heaters have the ability to withstand oxidation at high temperatures by forming a protective layer of quartz on its surface. If this glassy phase should be exposed to contaminants, a lower melting phase forms. This material literally drips off the element exposing more molybdenum disilicide on which a new protective

oxide layer forms.

MoSi2 heater become somewhat ductile at approximately 1200 C.

Advantages:

Moly-D elements may be used up to a surface temperature of 1800C in oxidizing atmospheres.

Long service life and ease of replacement contribute to high furnace tilization and low maintenance costs .

New and old elements can be used together and in series.

Can dissipate high power loading.

Can be used continuously or intermittently.

Provide rapid furnace temperature ramping.