Views: 122 Author: Site Editor Publish Time: 2023-09-08 Origin: Site

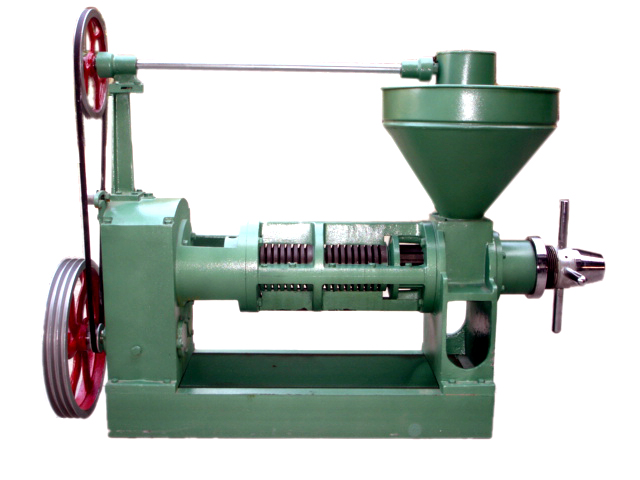

An oil expeller is a mechanical machine used to extract oil from various oil-bearing seeds or nuts. It works by applying mechanical pressure to the seeds or nuts, causing them to release their oil. This process is also known as oil pressing or oil extraction. Here's how an oil expeller typically works:

Feeding: The seeds or nuts (such as soybeans, sunflower seeds, peanuts, or canola seeds) are fed into the oil expeller's hopper or feeding chamber. The quantity of seeds/nuts can be controlled to maintain the desired throughput.

Pressing: Inside the oil expeller, there is a screw or an auger that rotates when the machine is powered. As the seeds/nuts are fed into the screw, they are progressively crushed and compressed against a cylindrical barrel or cage.

Heat and Friction: During the pressing process, the mechanical action generates heat and friction, which help in breaking down the cell walls of the seeds/nuts. This releases the oil trapped within the cells.

Oil Extraction: The crushed seeds/nuts are continuously pressed and moved along the barrel or cage by the rotating screw. As they move through the expeller, the oil oozes out of the seeds/nuts and flows through small openings or gaps in the barrel or cage.

Oil Collection: The extracted oil is collected in a separate chamber or trough, typically located at the end of the expeller. Some oil expellers have additional mechanisms to separate the oil from any remaining solids or impurities.

Residue Disposal: The remaining solid material, often called oil cake or meal, exits the expeller through another outlet. This residue can be further processed for various purposes, such as animal feed or as a source of protein.

Oil expellers come in various sizes and capacities, suitable for both small-scale and large-scale oil extraction operations. They are commonly used in the oilseed processing industry to produce vegetable oils for cooking, biodiesel production, and various industrial applications.

Oil expellers offer several advantages, including efficient oil extraction, relatively simple operation, and the ability to process a wide range of oilseeds and nuts. However, the quality and yield of the extracted oil can vary depending on factors such as the type of oilseed, the condition of the seeds, and the settings of the expeller. Additionally, some oilseeds may require additional pre-processing, such as dehulling or cooking, to optimize oil extraction.